- Introduction to Karakuri

- Basic Karakuri Units

- Karakuri Applications

- Ordering Karakuri Units

How Does Karakuri Work?

Working Smarter

SUS's Karakuri Mechanisms utilize gravity and the natural weight of items to achieve simple automation. Many tasks that once required an operator can now be unmanned. And because traditional karakuri mechanisms don't require electricity, operational costs are minimized for truly lean manufacturing.

Link Mechanism

The Link Mechanism consists of joints specially designed to be long lasting. Its ability to convert between circular motion and linear force makes it useful for a wide range of applications.

Movable Pulley

The Pulley System demonstrates the relationship between force and distance. By understanding the basic principles of pulleys, you can move items long distances or change the effort needed to move a load.

Karakuri Training

Simple Automation

Karakuri Training

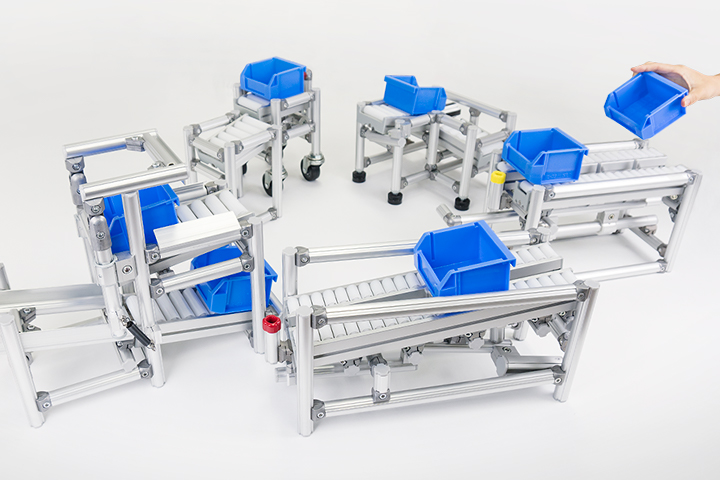

Miniature karakuri are the perfect tool for learning lean automation. Easy to build, these kits teach how and why karakuri automation works. Each kit includes all parts, assembly instructions, and parts list.

Starter Package

Karakuri Training

Packages include all of the necessary frames, connectors, and motion parts to build full sized karakuri or standard structures. Drawings and parts lists are also included.

Turns

The corner table rotates 90 degrees and then returns to its original position via counterweight. The orientation of the tote is maintained.

The corner table tilts and then returns to its original position via counterweight. The orientation of the totes changes.

Stoppers

The intermittent stopper rotates, allowing the tote to move forward. Any subsequent totes would be held in place by the rear arm of the stopper.

Depressing the foot pedal activates the see-saw and releases the front tote while simultaneously holding back any subsequent totes.

These pages showcase 18 of SUS’s most popular Karakuri units in action. Many of the structures seen here are found in the Ready Solution Catalog.

To see dozens of additional videos, including assembly, tips, and new designs, visit SUS America on YouTube.

Flip-flop Chuter

Discharge Trolley

Horizontal Turn

AVG Dispense/Receive Trolley

Stopper (See-saw)

Elevator

Zig-zag Chuter

Flip-up Trolley

Palette Chuter

Elevator for Large Totes

Level Lifter (Spring)

Unstacker

Automated 90° Turn

Overpass Transfer

Electric Lifter

Automated Flip-flop Chuter

Electric Level Lifterr

Electric Transfer Table

How to Order Karakuri Units

SUS America offers two different ways to order karakuri units:Ready Solution Kits and Custom Structures.

Ready Solution Kits

14 different Karakuri units are available as shown in the Ready Solution Catalog, pages 60-66. These units arrive as ready-to-assemble kits in the dimensions listed below.

If you would like different dimensions to suit your unique tote size or space requirements, contact SUS America with your specifications to receive adjusted pricing and lead times.

Custom Structures

SUS provides services for both custom karakuri units and static structures. Contact SUS America with as much detail as possible about your goal and needs. A solutions representative will then get in touch with you to discuss your project. Below you can see the general process for designing, creating, and delivering a custom karakuri unit.

Contact SUS

Contact SUS via email, phone, or directly through our website. Let us know about you and the situation you'd like help with.

The more details you give us the more efficiently we can move towards a solution.

SUS Visits Your Site

After seeing the area you want to improve, SUS will sit down with you to discuss possible solutions and build your company profile.

This ensures fast, accurate service throughout the process.

Receive a Sketch and Estimate

Depending on the complexity of your situation, you will receive a sketch and estimate after a few days or a few weeks.

This will include the lead time, assembly options, and purchasing preferences.

Make adjustments

Discuss the sketch and estimate with your team to see if there are any features that need adjustment.

If you'd like, SUS can visit your site again to talk about alterations and further options.

Send in a Purchase Order

Once we receive your purchase order, SUS processes your request and begins working on your structure.

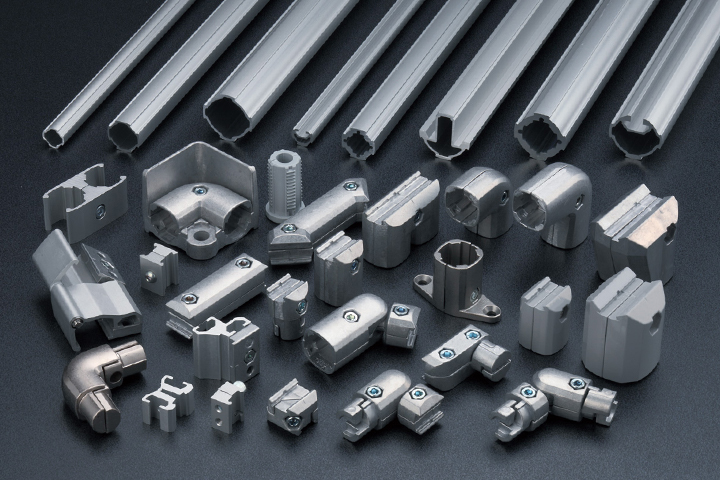

Cutting and Assembly

Frames and connectors are prepared to millimeter precision and assembled by expert technicians, or packed into a ready-to-assemble kit.

Shipping

The structure is carefully packaged and shipped to your location according to your instructions.

Check-up

SUS visits your site again to discuss any additional adjustments and continued improvements.